Formulation / Melting

The first step is to melt gold with minute amount of silver and copper. Silver and copper are blended because 99.99% gold is too soft to be pounded into thin leaf.

The melting pot is heated to 1,300 Centigrade and gold, silver and copper are added.

Wait for 10 - 15 minutes to completely melt, and pour into the molds to shape.

The melting pot is heated to 1,300 Centigrade and gold, silver and copper are added.

Wait for 10 - 15 minutes to completely melt, and pour into the molds to shape.

Tourist Facility HAKUKOKAN

Tourist Facility HAKUKOKAN See

See Taste

Taste Experience

Experience Buy

Buy Product/Service

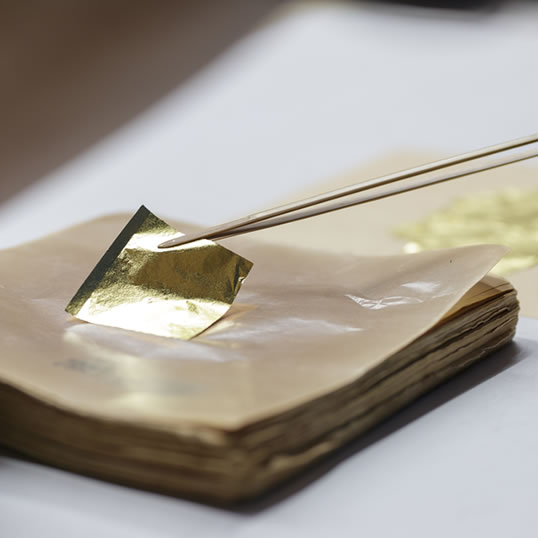

Product/Service Gold Leaf Craft

Gold Leaf Craft Cosmetics and Oil Blotting Paper

Cosmetics and Oil Blotting Paper Edible Gold Leaf

Edible Gold Leaf Metal Leaf Material

Metal Leaf Material